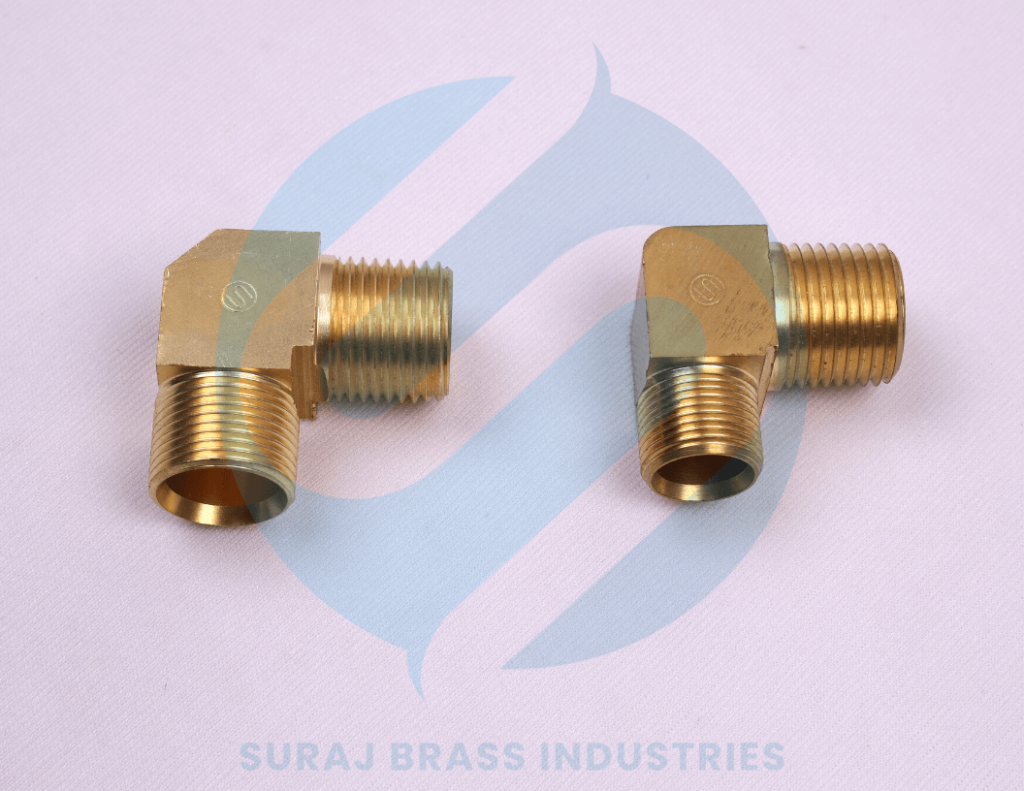

Industries such as plumbing, HVAC, gas pipelines, and industrial machinery rely heavily on brass elbow fittings to enhance fluid flow and join pipes seamlessly. These components change the direction of fluid flow while ensuring leak-tight, secure, and robust connections through and to the fitting.

Have you ever considered the manufacturing process of such small yet crucial components? The production journey of brass elbow fittings commences with raw brass material that goes through multi-step and precision engineering processes to become high-quality, ready-to-use fittings.

This blog takes you through the entire process of manufacturing these fittings from selecting raw brass to forging, machining, finishing, and final quality testing so you can appreciate why precision is critical in brass elbow production.

The Raw Material: Selecting High-Quality Brass

The manufacturing of brass elbow parts starts with sourcing high-quality brass alloys. Brass is an alloy of copper and zinc known for corrosion resistance, strength, and ability to be easily machined.

- Depending on the industry application and environmental exposure, we use different compositions of brass for the elbows.

- Brass elbow manufacturers in Jamnagar make sure that the sourced brass is top-grade, as this enhances the durability and longevity of the fittings.

- Brass Forging Parts have greater strength, better resistance to temperature and pressure fluctuations, and improved grain structure when compared to cast brass, and therefore, they are used far more frequently.

It is important to pay attention to the composition of brass because poor quality brass tends to wear out too quickly, develop leaks in critical areas, and fail in its primary functions.

Brass Forging & Shaping: The First Steps in Manufacturing

The initial step in the forging process is the selection of the material; in this case, brass elbow fittings require casting or forging to generate shape.

🔹 Forging Process:

- Brass fittings are produced from billets by heating them and placing it under high pressure to form them into a desired shape.

- Compared to cast fittings, forged brass elbows are denser, stronger, and sturdier, making them much more reliable and, unlike them, not breaking easily.

🔹 Casting Process:

- One of the methods to manufacture brass elbow parts is pouring molten brass into a mold for the mold to shape them.

- Brass fittings are ideal for complex shapes, although better accuracy is often required, and thus, additional engineering work may be needed to achieve these standards.

Once forged or cast, the brass elbows move to machining for accuracy and finishing.

Precision Machining & Threading: Ensuring a Perfect Fit

The rough fittings for elbows of brass are subjected to extreme precision machining where their size is modified to pair with the threads, and they are readily available to use.

🔹 CNC Machining:

Brass elbow is shaped using CNC machines, which grant unparalleled precision.

This ensures consistency in dimensions, shape, and threading, which is necessary for achieving tight and leak-proof fittings.

🔹 Threading Process:

- Brass elbow suppliers offer fittings with internal and external threads for simple fitting purposes.

- Sufficient threading guarantees proper connections with other plumbing and industrial equipment.

Threading and machining are two principles that guarantee reliable operation of brass elbow fittings in high-pressure and temperature environments.

Surface Finishing & Coating for Durability

In order to withstand corrosion, brass elbow parts undergo various finishing processes for longevity:

✅ Polishing & Buffing: Gives a smoother and polished surface.

✅ Electroplating: Improves corrosion resistance by adding a protective metal layer.

✅ Nickel or Chrome Coating: Done for aesthetics as well as extra strength.

Brass fittings came under such rigorous examination because they are used in marine environments, chemicals, and industrial purposes where moisture tends to corrode parts.

Quality Control & Testing: Ensuring Strength & Leak Resistance

These brass elbow fittings have already undergone significant quality control procedures in relation to industry standards before coming to market.

Dimensional Accuracy Testing: Each fitting is verified against the level of size and tolerance.

Leakage & Pressure Testing: Checks if brass elbow suppliers leak and pressure-resist fittings.

Thread Strength Testing: Ensures that the exporting company delivers well-threaded components that will last.

Only fittings that conform to these standards are sealed and made ready for local and foreign markets.

Packaging & Global Distribution: From Manufacturer to Market

Suraj Brass Industries, a predominant manufacturer of brass elbows, ensures no brass elbow fitting is left unpackaged so that they do not suffer any damages during transit.

🔹 Bulk Packaging for Export: Take care of efficient and safe shipping all over the world.

🔹 Customized Orders: Manufacturers export brass elbows from Jamnagar in large quantities to cater to different industries.

🔹 Global Reach: Supplied to the USA, UK, Europe, Australia and other countries as exporters of brass elbows.

Through effective supply chain management, we ensure reliable supply and timely delivery for every industrial and commercial requirement.

Why Choose Suraj Brass Industries for Brass Elbow Fittings?

✅ Premier brass elbow manufacturers in Jamnagar with a wealth of experience spanning decades.

✅ Superior quality fittings made from brass with high strength and accuracy.

✅ Manufactured under ISO certification to meet the global standards.

✅ Reliable suppliers and exporters of brass elbows internationally.

✅ Customization Offered: Brass elbow fittings can be designed to meet particular specifications of customers.

At Suraj Brass Industries, we guarantee that our quality brass elbow fittings will outlast the competition.

Conclusion: The Journey from Raw Brass to Precision Elbow Fittings

To ensure that customers receive nothing less than the best, the transformation of brass into elbow fittings requires sophisticated material selection, in-depth machining, quality assurance checks, and a lot of attention to detail.

Suraj Brass Industries is best suited to help clients who are looking for quality, corrosion-resistant, and precision brass elbows.

Get High-Quality Brass Elbow Fittings Today!

📞 Call Us: +91-9227022044

📧 Email Us: info@surajbrassindustries.com

Order now and get the best brass elbows at competitive prices!