Introduction

In the engineering and construction sectors, mild steel is a basic material that offers versatility and cost-effectiveness. Primarily consisting of a high iron content with very little carbon, mild steel is renowned for its ductility, weldability and malleability. These intrinsic qualities make Mild Steel Components indispensable in creating anything from structural frames to intricate machine parts.

The use of mild steel is vital in the construction and engineering industries because it is strong and flexible enough to meet both structural requirements as well as budget limitations. This blog examines the importance of Mild Steel Components in these fields, emphasizing how they affect modern infrastructure durability and strength.

The Properties of Mild Steel That Benefit Construction and Engineering

Properties that particularly cater to needs of the field of construction and engineering are what makes mild steel outstanding:

Durability: With its sturdiness, mild steel ensures that structures can be exposed to wear without at a glance fading away thereby making it dependable for use over a long period.

Weldability: Mild steel has this feature which means easy joining thus facilitating smooth connections required for complex infrastructural undertakings.

Malleability: The ability of mild steel to be formed into various shapes supports bespoke designs ranging from support beams to fine fittings.

Wide Range of Applications in Construction

Mild Steel Products have an important role in constructing any structure since they offer critical support across numerous structural applications:

Beams And Frames: Serve as the skeleton for buildings and structures, offering strength and support.

Reinforcing Bars: These help improve concrete tensile strength. This is necessary especially in huge constructions like bridges or tall storey buildings.

Examples are given below about Mild Steel Fittings used for their mechanical integrity :

Skyscrapers: Usefull when subjected under severe amounts of pressure by high altitude environments that only midl steels could thrive through.

Bridges: Depend on the robustness of mild steel to support the weight and continuous traffic, demonstrating the material’s reliability and endurance.

Essential in Engineering Projects

Different engineering disciplines depend on mild steel for a variety of reasons including being versatile and reliable:

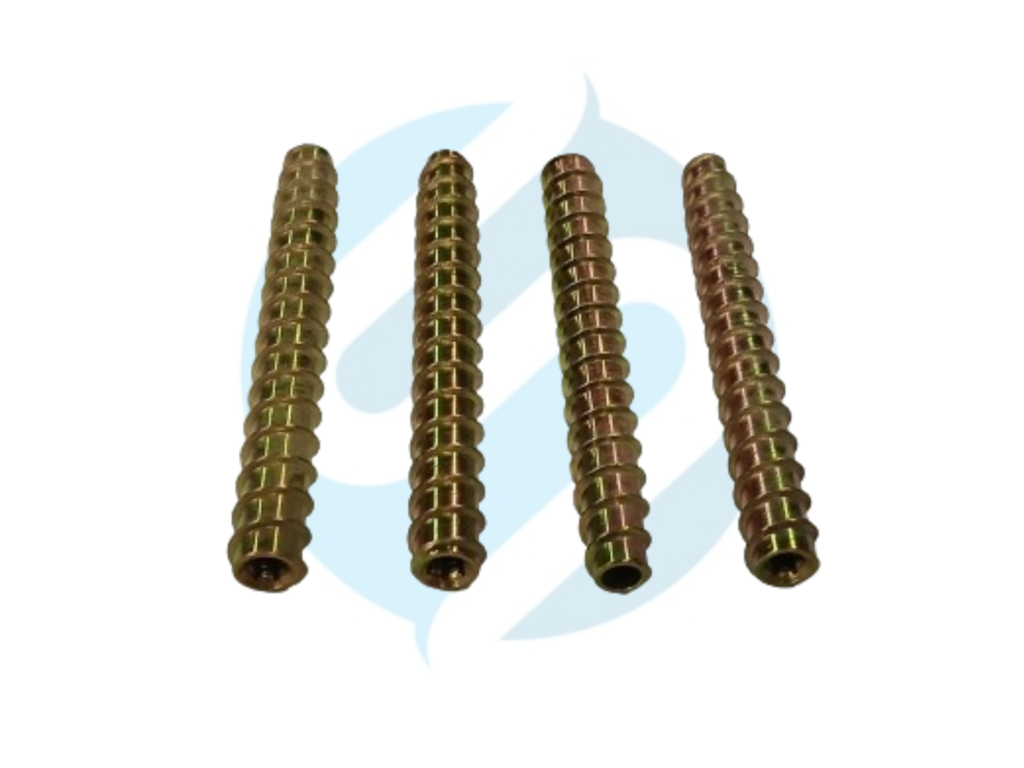

MS Fittings and MS Hydraulic Fittings:

These are essential parts in mechanical and civil engineering due to their ability to withstand high pressures as well as ensuring secure connections. In hydraulic systems, MS Hydraulic Fittings ensure robust performance and leakage prevention, critical in maintaining system integrity.

MS Auto Accessories and MS Components:

Besides enhancing the vehicle’s aesthetics and structural strength, mild steel is used extensively in the automotive industry. For instance, MS Auto Accessories comprises of chassis parts as well as ornamental-wood decorations that provide both classiness and quality which can be used to meet consumer demands all while ensuring safety.

Advantages of Mild Steel Components in Manufacturing

There are several attributes of mild steel that make it one of the most preferred metals for manufacturing:

Cost-Effectiveness and Availability:

One major benefit of mild steels is its cost effectiveness plus wide availability; hence it is widely used in mass manufacturing across many industries ensuring affordability without compromising on quantity.

Precision Manufacturing:

Due to technological advancements, accuracy has been achieved with Mild Steel Precision Parts as well as Mild Steel Turning Parts. This is very important when components have to be fitted within tight tolerances such those found in aerospace or precision engineering applications.

Customization and Flexibility

This however, makes mild steel not only strong and cost-effective but also very versatile, which is why it can be used in custom applications across a wide range of industries.

Versatility of Mild Steel Customized Parts:

Mild Steel Customized Parts and Custom Mild Steel Parts are tailored to meet the unique demands of specific projects, allowing for bespoke solutions that fit exact specifications. This customization capability is crucial in sectors requiring non-standard component sizes or shapes.

Innovative Designs and Tailor-Made Solutions:

The malleability of mild steel permits innovative design flexibility, enabling engineers and designers to overcome complex engineering challenges with tailored solutions. Whether for architectural frameworks or intricate machine parts, mild steel’s adaptability ensures optimal functionality and integration.

Elevating Manufacturing Efficiency with Metal Sheet Parts and Components

Conclusion

In this discussion we have been looking at the place of Mild Steel Components in Engineering and Construction. These elements are highly regarded because they play a key role in several projects’ physical as well as mechanical integrity around the world. The combination of strength, versatility, and cost efficiency has made it an unrivaled metal choice over time that can meet both contemporary dynamic engineering requirements as well as construction’s strict standards.

Further exploration into the benefits and uses of Mild Steel Components is therefore encouraged among industry stakeholders including project managers. Therefore consider these robust materials whenever you are thinking about your next undertaking as they will enhance durability, malleability, and affordability. For more information or a variety of mild steel parts you can check our page on Mild Steel Products or contact us. At this site you will also get acquainted with custom-made solutions best suiting your specific requirements so that your project may benefit from all advantages attached to this material type.