Introduction

Zinc, a metal known for its versatility and widespread application across various industries, plays a pivotal role in modern manufacturing. As a key component in everything from automotive to electronics, zinc’s properties of durability, malleability, and excellent corrosion resistance make it an ideal choice for numerous industrial applications.

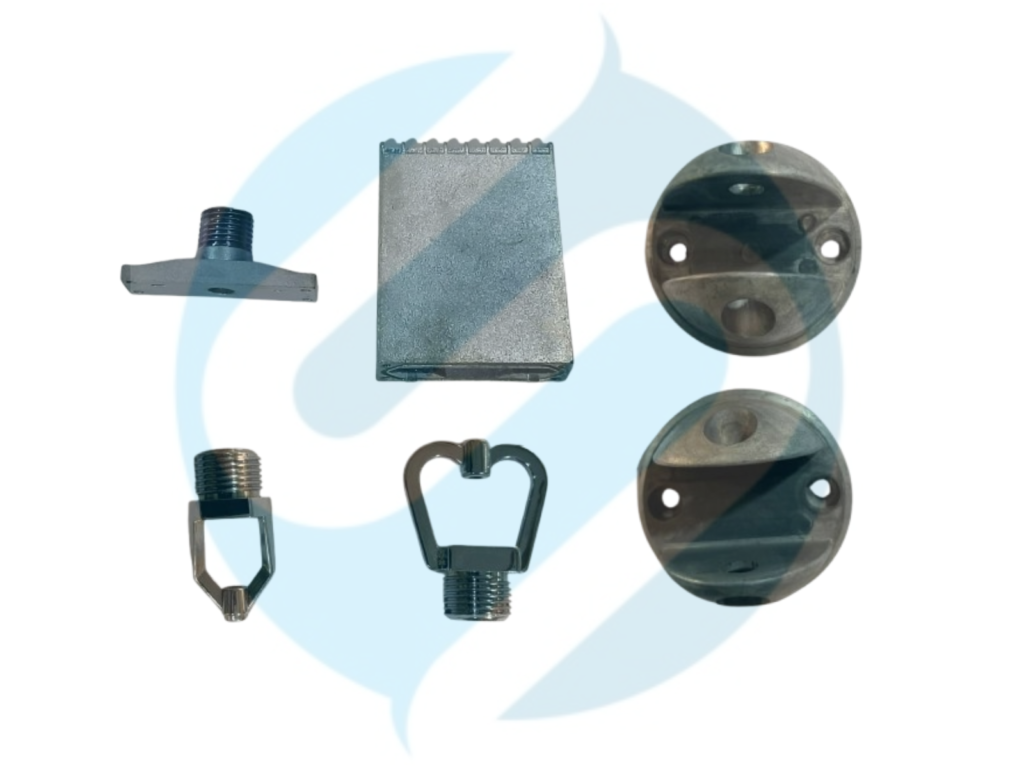

This blog explores the significant advancements driven by High-Quality Zinc Parts, emphasizing how they enhance industrial processes and product functionality. By delving into the essential benefits and uses of zinc, we will uncover why this material is so valued in today’s fast-paced manufacturing sectors and how it continues to push the boundaries of innovation and efficiency.

Properties of Zinc that Benefit Industrial Applications

Zinc stands out in the manufacturing world due to its remarkable properties, which cater perfectly to the rigorous demands of various industrial applications. Here are some of the key characteristics that make zinc an indispensable material in sectors ranging from construction to high-tech industries:

Durability:

Zinc is highly durable, able to withstand harsh environments without succumbing to wear. This makes Zinc Alloy Components especially valuable in industries where longevity and reliability are crucial, such as in automotive and building materials.

Corrosion Resistance:

One of zinc’s most notable attributes is its excellent resistance to corrosion. This property is essential for outdoor applications and in environments where materials are exposed to moisture, chemicals, or saline conditions. The ability to resist rust extends the life of products significantly, making zinc a cost-effective choice for long-term projects.

Malleability:

Zinc’s malleability allows it to be easily shaped into intricate designs without breaking, making it ideal for detailed Zinc Parts Manufacturing. This flexibility is particularly beneficial in creating complex parts needed in machinery and decorative elements in construction.

Manufacturing Process of Zinc Parts

The manufacturing of zinc parts involves sophisticated techniques that capitalize on zinc’s unique properties, enabling the production of components with precise specifications and high-quality finishes. Here’s an overview of the key manufacturing processes used for zinc parts:

Die Casting:

Zinc die casting is one of the most common methods for producing zinc parts, particularly for large volumes. This process involves injecting molten zinc alloy into a die or mold at high pressures. Zinc Die Casting Parts are known for their high dimensional accuracy and complex geometries, which are difficult to achieve with other metal alloys. This method is highly efficient and cost-effective, making it ideal for producing parts like gears, fittings, and casing components.

Machining:

After die casting, zinc parts often undergo further machining to refine their shapes and achieve tighter tolerances. Precision Zinc Machining involves various techniques such as milling, turning, and drilling, which allow for the creation of highly specific and detailed component features. This step is crucial for applications requiring exceptionally high precision, such as in automotive assemblies and electronic devices.

Applications of Zinc Parts in Key Industries

Zinc’s unique properties make it an essential component across various industries, each leveraging its benefits to enhance their products and processes.

Automotive:

In the automotive sector, Zinc Parts are extensively used due to their durability and cost-efficiency. They are commonly found in safety components, body panels, and trim parts where strength and lightweight properties are crucial. The corrosion resistance of zinc also ensures that these parts withstand environmental stresses and prolong the vehicle’s lifespan.

Electronics:

Zinc plays a critical role in the electronics industry, particularly in casing and shielding components. These Zinc Metal Products provide effective electromagnetic shielding, protecting sensitive electronic equipment from interference while also offering physical protection.

Construction:

In the construction industry, zinc is valued for its use in building hardware and fixtures such as door handles, locks, and architectural metalwork. The material’s ability to resist weathering and corrosion makes it ideal for both interior and exterior applications, ensuring longevity and maintaining aesthetic appeal over time.

Benefits of Using Zinc Parts

The use of zinc in manufacturing offers several key advantages that make it a preferred choice over other metals:

Cost-effectiveness:

Zinc is often more economical than other metals used in similar applications, offering significant cost savings, especially in large-scale production settings. This affordability does not compromise quality, making zinc an attractive option for many manufacturers.

Longevity and Low Maintenance:

Due to its excellent corrosion resistance, Zinc Metal Products often require less maintenance compared to parts made from less durable materials. This longevity is crucial in reducing the total cost of ownership and enhancing the sustainability of the products.

Customization Possibilities:

With techniques such as die casting and machining, Custom Zinc Parts can be tailored to meet specific design requirements. This flexibility allows manufacturers to create unique solutions for complex challenges, ensuring that the final products are not only functional but also aligned with specific customer needs.

Conclusion

Throughout this discussion, we’ve delved into the substantial role that zinc parts play in driving efficiency and fostering innovation across multiple industries. From automotive to electronics and construction, the versatility and benefits of zinc have proven indispensable. The unique combination of durability, cost-effectiveness, and customization possibilities make Zinc Metal Products a pivotal resource for modern manufacturing needs.

As a leading Zinc Parts Supplier, Suraj Brass Industries is committed to providing high-quality zinc solutions tailored to meet the diverse requirements of our clients. Our expertise in crafting Custom Zinc Parts ensures that each component not only meets but exceeds industry standards, providing you with the reliability and performance necessary for your demanding applications.

We invite you to Contact Suraj Brass Industries to discover more about our comprehensive range of Zinc Parts and explore the possibilities with our Custom Zinc Parts. Our team, led by our knowledgeable Sales Head, Amit Bhanderi, is ready to assist you with expert advice and tailored solutions that align perfectly with your specific needs. Visit our Zinc Products for more detailed information and to make inquiries about how we can support your projects with superior zinc components.

Choose Suraj Brass Industries as your trusted partner for all your zinc component needs and experience the commitment to quality and customer satisfaction that sets us apart.

Exploring the versatility of zinc parts further highlights our commitment to enhancing industrial efficiency, much like our focus in the recent blog post, ‘Elevating Manufacturing Efficiency with Metal Sheet Parts and Components.‘ To see how these components integrate seamlessly with zinc parts in streamlining manufacturing processes and improving product durability, click here to read more.