Brass tees are versatile fittings used in plumbing, HVAC, and industrial applications, facilitating the connection of three pieces of piping for easy air, heating, and cooling, or process flow. The toughness and corrosion-resistant properties of the metals make them essential in conditions that require strength and durability.

When selecting fittings, various materials such as stainless steel, copper, PVC, and iron are available, each offering unique advantages and limitations. It’s imperative to pick the right one, as it helps solve certain project problems and avails reliable services.

This blog will compare brass tees with other fitting materials, elucidating why brass is typically the preferred choice. By the end of this guide, you will know more about which fitting material is better for your project.

Understanding Brass Tees

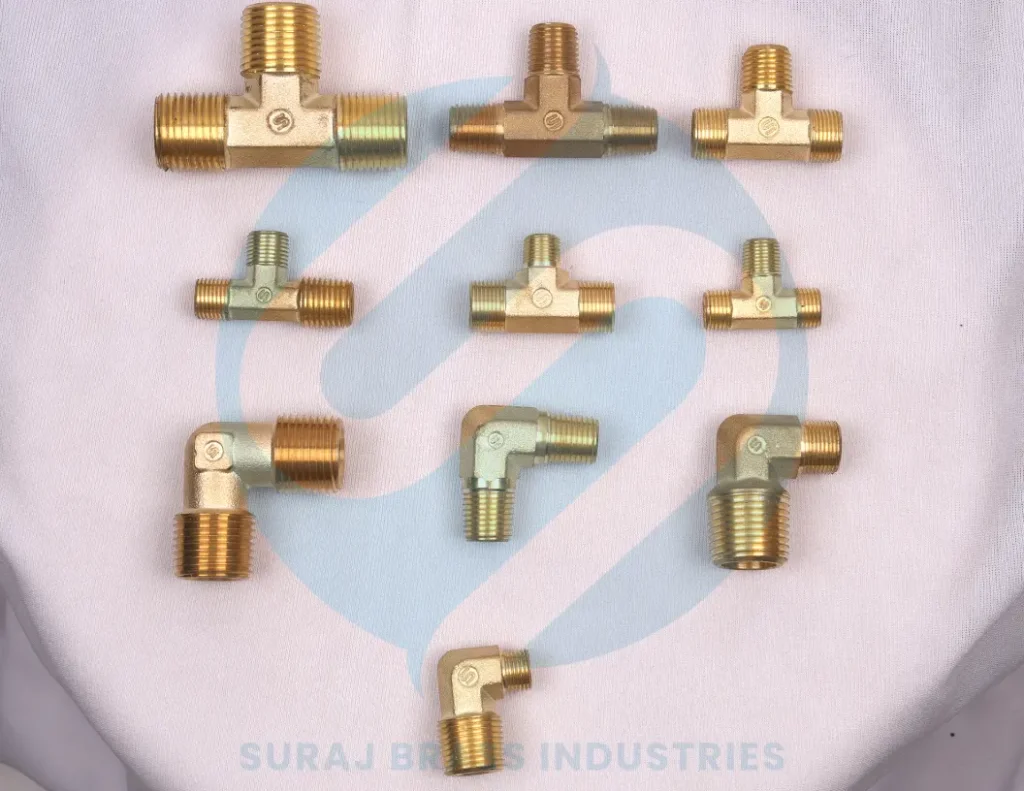

The T-shaped brass tee is a piping fitting that connects the ends of three pipes at right angles, two of which are straight, while the third is perpendicular to the two. Brass tees are an alloy of zinc and copper, which predominantly finds application in plumbing, HVAC, automotive, marine, and even industrial applications because of the need for dependable distribution of fluids or gases.

Any of the fabrication methods, such as precision casting, forging, and machining, can ensure uniformity in thickness, dimensions, and fine finishes. This plus the good workmanship boosts leakage shielding and overall functioning, making brass applications appropriate for extreme conditions.

Understanding the process of making brass tees is beneficial as it explains why these tools can withstand high pressure and outlast other tools.

Overview of Other Common Fitting Materials

When searching for and purchasing pipe fittings, different materials are beneficial for different applications.

Stainless Steel Stainless steel fittings have high durability and resist rusting, making them good for heavy duty and high- or low-temperature operations such as in the chemical and food production industries. They, however, are more expensive when compared to other materials used.

Copper:

This is a preferred material in plumbing and HVAC systems since it has high thermal conductivity and is resistant to corrosion. It can cope with hot or cold water systems. However, copper is on the softer side and not ideal for high-impact applications since brass or stainless steel materials offer better hardness.

PVC (Polyvinyl Chloride):

PVC fittings are cheap, light, and rust-resistant. These attributes make PVC pipe fittings most common in domestic plumbing and irrigation. However, they are limited in their ability to withstand hydrostatic or hydrothermal pressures. They also tend to become brittle over time.

Iron:

Iron fittings, whether cast iron or malleable iron, are typically robust enough to withstand harsh conditions like drainage and waste systems. However, improper painting or use in high-corrosion environments can cause oxidation on iron fittings, limiting their use in wet environments.

While each of these materials has unique qualities that make them ideal for a particular application, some, like ms fittings, may have limitations in terms of functionality, corrosion resistance, or longevity.

Key Factors to Consider When Choosing Fittings

When designing systems, keeping the following facts in mind can improve the selection of materials for fitting components and their long-term performance:

Durability and Longevity:

The material Environmental conditions can cause limitations or failures due to endurance wear, thrust, or corrosion. Brass material has been known to withstand high durability and is therefore appropriate for both low and high pressure systems.

Corrosion Resistance:

This crucial factor ensures the absence of leaks and prevents a system from catastrophic failure. Brass fittings are known to perform efficiently in this region, especially in water and/or sea environments, rather than iron or iron alloys.

Strength and Pressure Handling:

While stainless steel achieves the highest tensile strength, brass excels in balancing tensile strength and flexibility, making it an ideal choice for various pressure levels.

Cost-Effectiveness:

Despite the most challenging circumstances, we must adhere to budgetary constraints. Brass fittings offer a balance between performance, cost, and time, potentially yielding future savings due to their durability and reduced maintenance requirements.

Ease of Installation:

The simplicity of fixing enhances the project’s duration and the level of skilled labor required. Brass fittings are simple to use when compared to iron fittings, which are heavy and unyielding and also require special adhesive for PVC.

Aesthetic Appeal:

In such situations, where the fitting is exposed, decorative designs are done in brass rather than mount PVC fittings.

Upon examining these factors, we can conclude that brass tees are typically high-quality and cost-effective. their reasonable quality for cost ratios in addition to ease of use.

Brass Tees vs. Other Fittings: A Comparative Analysis

Compared to other fitting materials, brass tees offer a few noteworthy advantages.

Durability:

Brass fittings are made in such a way that they remain in working conditions for long without breaking or being damaged, unlike most plastic materials, such as PVC, which become old and breakable over time, or iron materials, which eventually corrode. Stainless steel is equally tough.

Corrosion Resistance:

One significant advantage of brass is its excellent corrosion resistance, even in wet situations. While stainless steel materials are also capable of withstanding corrosion, other materials such as iron are susceptible to rust, and copper can also lose its effectiveness in certain environments. Plumbing, HVAC, and marine applications prefer brass because it remains durable.

Strength:

Brass is able to absorb impacts from varied angles of pressure without cracking due to the combination of strength and flexibility. On the other hand, while “stainless steel” boasts superior tensile strength, most industrial and household applications find cosmetic brass to be sufficiently strong, with an additional layer of plasticity to prevent brittle fracture.

Cost Comparison:

Brass fittings tend to be more affordable compared to the initial cost of stainless steel, which can be quite expensive. Plastic joints may initially seem inexpensive, but they lack the durability and, consequently, maintenance costs that brass fittings offer.

Installation:

Preparing brass tees for use is instigated by the fact that their composition is soft and the appropriate tools are commonplace. Iron fittings, due to their weight and attractiveness, tend to be bulkier and more complex, while PVC fittings require the use of specific glues. Brass simplifies the installation process and reduces the maintenance costs associated with it.

Why Brass is the Best Choice for Your Projects

Users can benefit from an unusual combination of factors when using brass tees.

Long-Term Dependability: Brass fittings are made with a degree of strength; therefore, they can be used for all projects, even where serious and long-lasting solutions are needed.

Outstanding Resistance to Corrosion: Torch coating brass, which seals off leaks and prevents corrosion traces, enhances its corrosion resistance in both plumbing and marine applications.

Strength in Diversity: Brass can perform both light and heavy-duty tasks because it can withstand all pressures.

Efficiency: The low cost and quality of brass fittings eliminate unnecessary costs that would arise from frequent replacements within a short period.

Quick Fit-In: Brass is easy to use, leading to faster fitting operations.

Brass tees are most relevant in a number of places, such as industrial piping, domestic plumbing, HVAC systems, and marine applications, where there is a need for high performance and resistance to corrosion.

Applications of Brass Tees Across Different Industries

Brass tees have broad acceptability in industries because they are practical and reliable.

Plumbing: Brass tee fittings are used in residential and commercial plumbing for piping branches distributions and drainage systems, where both temperature and varying pressure levels are present.

HVAC Systems: Brass tees control the flow of fluid or gas in heating, ventilation, and air conditioning (HVAC) circuits and can withstand temperature variations in service.

Automotive: In the fuel pipes and other fluid systems, when pressure and corrosion resistance are required, then brass fittings are used.

Marine: Due to the corrosive nature of saltwater, these fittings are made from brass since it does not rust easily, making it suitable for boats and other marine equipment.

Industrial Applications: Manufacturing and chemical plants widely use brass tees for fluid distribution due to their strength and reliability.

According to the ISO 9001:2015 certificate issued by Suraj Brass Industries, it is clear that our company, which manufactures brass fittings, adheres to high standards of quality and international policies regarding brass fitting production.

Exploring the Varied Uses of Brass Tees

Conclusion

Brass tees deliver unmatched advantages over other fitting materials, offering a blend of durability, corrosion resistance, and ease of installation. Their cost-effectiveness and versatility across various applications make them an excellent choice for projects needing reliable, long-term solutions.

For premium-quality brass tee fittings, explore Suraj Brass Industries’ wide range of options. Our commitment to quality, backed by ISO certification, ensures that our products meet the highest standards.

Visit Suraj Brass Industries or call us at +91-9227022044 to speak with our experts, request a quote, or find out more about custom solutions tailored to your project needs.