Brass Forging Parts

Brass Forging Parts

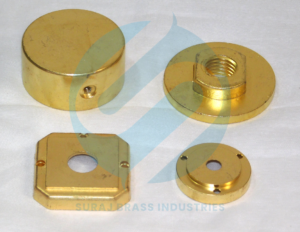

Suraj Brass Industries is involved in the production of a wide range of brass forging parts aimed at fulfilling the rigorous requirements of various industries. The performance characteristics of our brass forging components reflect our guiding principles of quality, innovation, and customer satisfaction.

Compressing a piece of brass alloy at an elevated temperature creates brass forgings, which are strong, durable, and resistant parts. The forging process serves to improve the mechanical characteristics of brass, which makes brass forging parts popular in applications with requirements for high strength, reliability, and safety.

Why Choose Brass Forging Parts?

Brass forging parts are unique because of the properties and advantages they possess over the other manufacturing processes. Let’s explore why brass forging parts are the preferred option:

Superior Strength

Compared to cast or machined parts, forged brass components are much stronger. The forging procedures increase the material’s strength by aligning the grain structure.

Corrosion Resistance

Brass is extremely resistant to corrosion, which allows use in the most humid habitats or even with chemically harsh environments.

Dimensional Accuracy

All parts undergo the most precise forging in order to fit into specific angles with the utmost precision.

Excellent Flow Characteristics

The forging parts can also be deeper and more intricate thanks to brass’s hot-working features, which allow it to flow during the forging process.

Aesthetic and Functional Appeal

Brass forging parts are relatively easy to bore holes into and have an immaculate finish; hence, they have a visual and functional appeal.

Applications of Brass Forging Parts

Due to their exceptional characteristics of strength, durability, and precision, our brass forging parts are applicable in a wide range of industries. Let’s briefly look into their few key applications:

- Automotive Industry

Brass forging parts are heavily utilized in crucial automotive parts such as fittings for fuel systems, brake assemblies, and engine components.

- Plumbing and Valve Fittings

Due to their corrosion resistance properties, these parts are ideal for use with water and valve fittings, guaranteeing strong and leak-free connections.

- Electrical and Electronics

Electrical connectors, terminals, and various switchgear components use forged elements due to the high conductivity of brass.

- Hydraulics and Fasteners

Hydraulic systems and fasteners widely use forged brass elements due to their high strength and reliability.

- Aerospace and Engineering

These components, with their outstanding precision and strength, find widespread use in high-performance aerospace and engineering applications.

Features of Brass Forging Parts

Our brass forging components, forged in bronze, are believed to possess numerous features that make them ideal for use in the following industries:

Dimensional Accuracy: We manufacture components within the design limits and specifications.

Corrosion Resistance: Brass’s inherent nature ensures the durability of its mechanical properties under these conditions.

Easy to Install: Specialized designs allow for seamless integration into various systems without any difficulties.

Immaculate Finish: A lovely and smooth surface enhances the functionality and aesthetics of the component as well.

High Strength and Durability: Despite exposure to high pressures and stress, the forged part’s performance remains unaffected.

Why Choose Suraj Brass Industries for Brass Forging Parts?

1. Advanced Manufacturing Capabilities

At Suraj Brass Industries, we use state-of-the-art forging equipment and techniques to produce brass forging parts that meet the highest standards of quality and precision.

2. Custom Solutions

Meeting customer standards is important, and we understand that each project has unique criteria. Therefore, we prepare a cut instrument and fabricate components according to the developed outlines.

3. ISO-Certified Excellence

The management system comprises all functions and relationships that dictate quality. Because of the approach, Suraj Brass is an ISO 9001:2015 certified company.

4. Global Reach

We confidently conduct business overseas, exporting brass components to various countries, such as the USA, UK, Australia, Mexico, Brazil, and many more within Europe and around the world.

5. Experienced Team

Suraj Brass Industries boasts an in-house quality lab, fully equipped with all necessary testing equipment. Suraj Brass Industries employs skilled professionals who oversee every step of the production and testing process, from selection to delivery.

Customization Options for Brass Forging Parts

Brass forging components can be made to specific requirements thanks to our full customization service. Such customization may encompass the following:

Material Composition: The material composition consists of special brass alloys as specified by our clients.

Design and Dimensions: Special shapes, sizes, and designs are specifically made for their respective applications.

Surface Finishes: Such as polishing, plating, and coating, to provide extra protection against damage and enhance appearance.

Threading and Machining: To ensure a proper fit, we can cut threads both internally and externally through machining.

Our Commitment to Quality

Suraj Brass Industries is all about quality in every product. We thoroughly test every single part of brass forging to meet the highest quality metrics for strength, durability, and performance in any activity. Our rigorous efforts, from inspecting the raw material to testing the final product, guarantee you get parts that you can rely on.

Conclusion

Brass forging parts are easily the most reliable components because they can withstand a high amount of pressure and are malleable. These qualities make them useful in all sectors that require strength and the capability of performing under stress. Suraj Brass Industries has experienced skilled craftsmen in every brass forging component they do and possesses far superior equipment, giving them an advantage over the competition.

Call upon us to assist in designing parts or even acquiring standard components because we assure you that our services will gladly take care of your brass forging part requirements.

Looking for reliable and high-quality brass forging parts? Get in touch with Suraj Brass Industries now to explain your needs and see our products.

Contact Us:

You can go to Suraj Brass Industries or telephone us at +91-9227022044 for any questions and price inquiries.

Call to ask any question

Product list of brass forging parts :

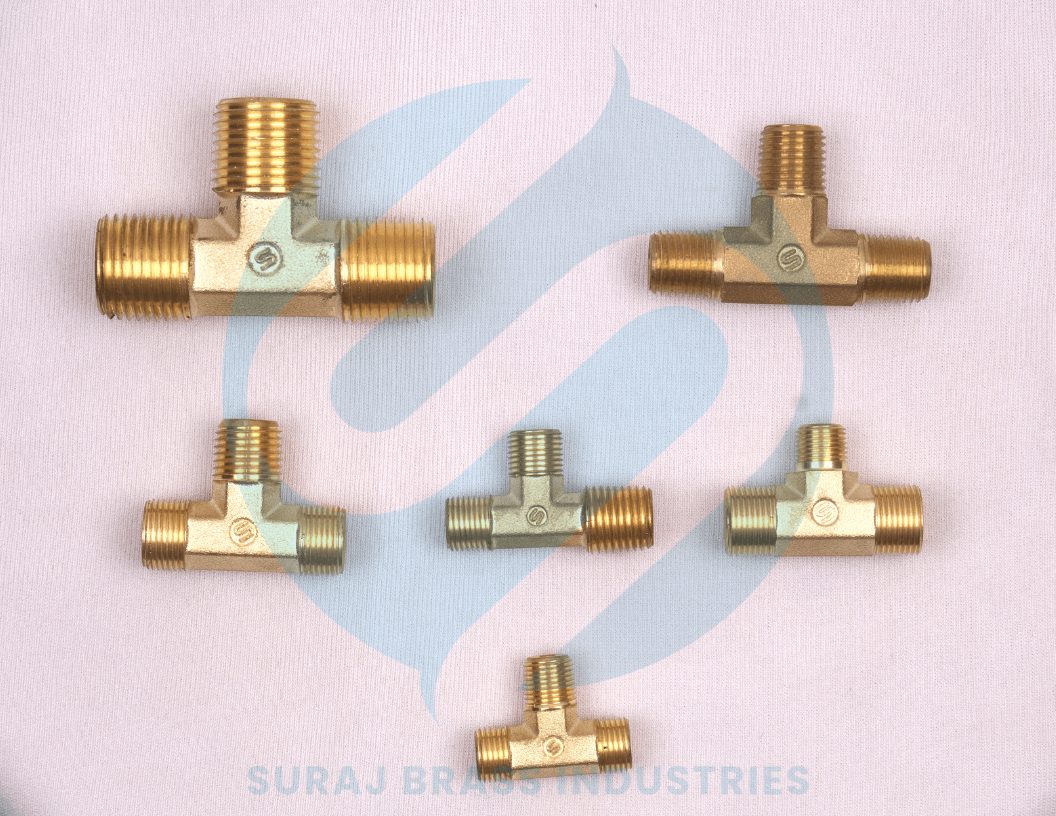

Brass Tee Fittings

We Suraj Brass Industries manufacturing standard and good quality brass tee, We [...]

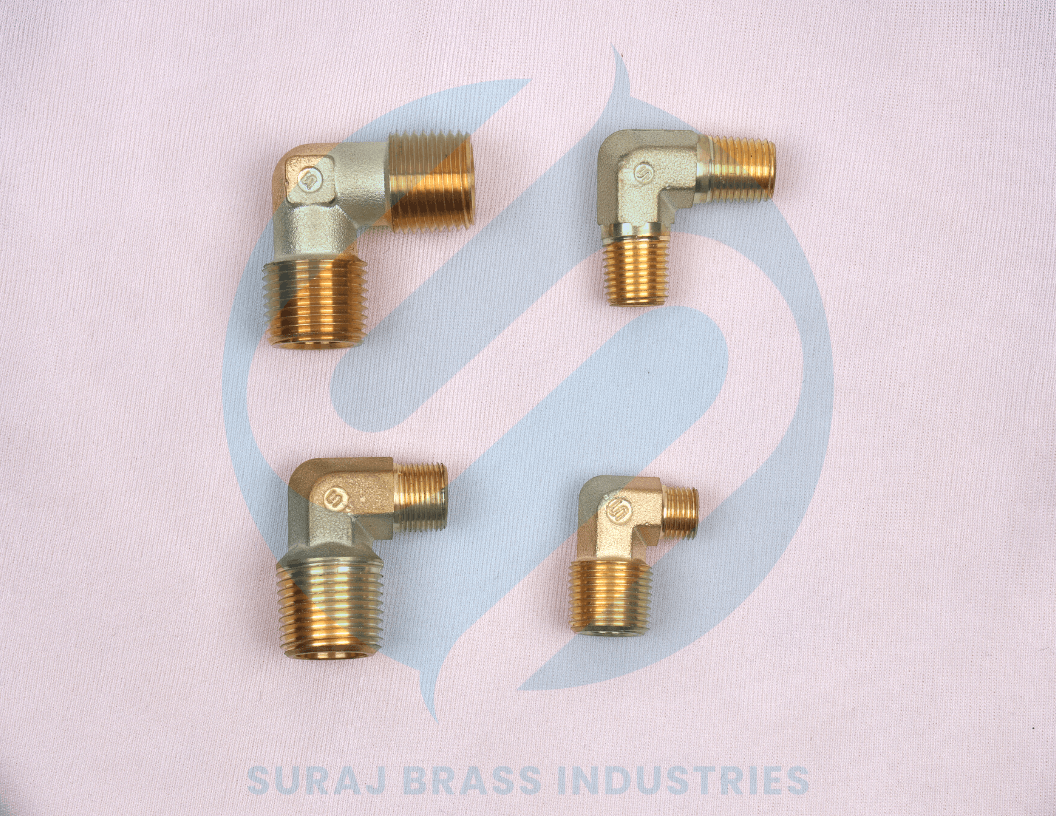

Brass Elbow

We are listed at the apex in the list of the well-reputed [...]

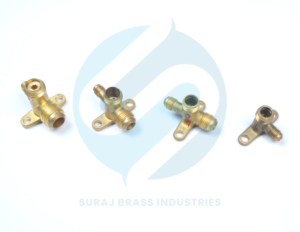

Brass Nozzles

Suraj Brass Industries, the leading organization in the brass manufacturing industry, [...]